- Our Brands

- Products & Solutions

- About Us

-

-

About Us

-

-

- Resources

- Contact Us

-

-

Contact Us

-

-

-

-

- Join Us

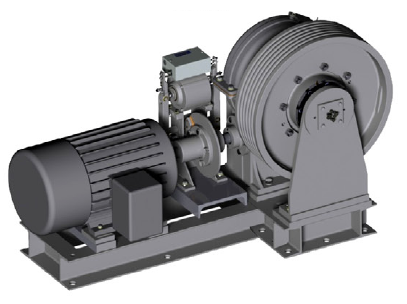

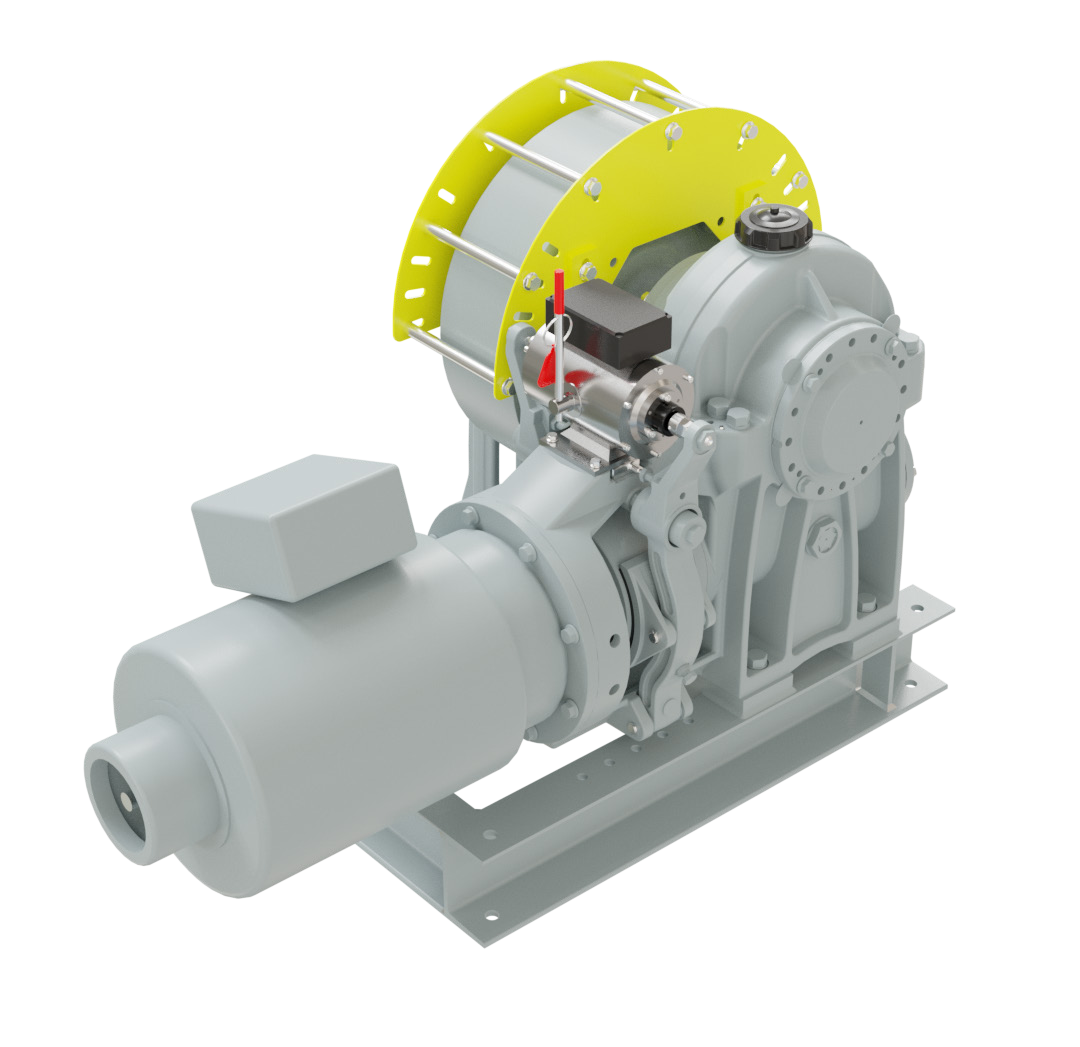

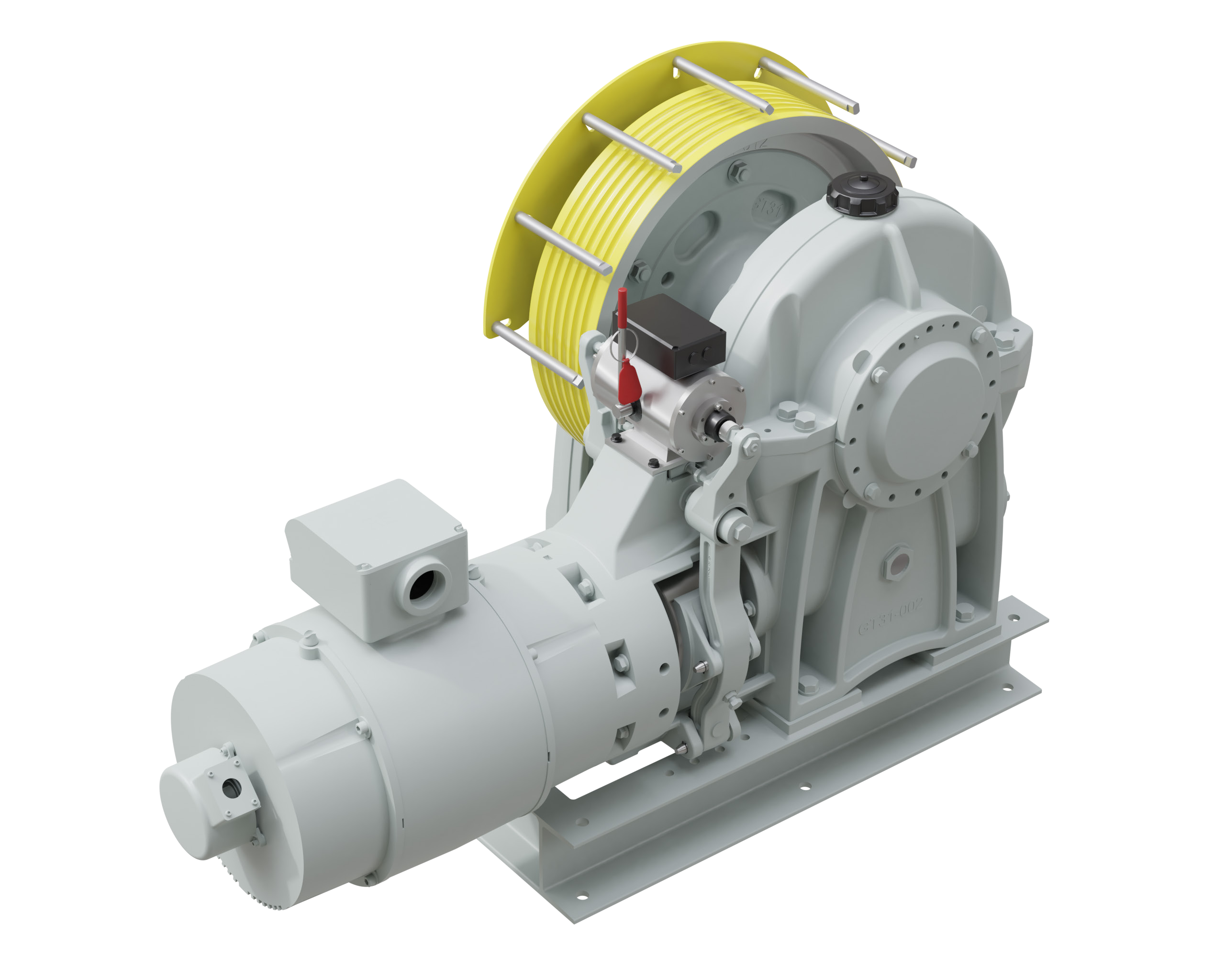

These machines are designed for installation where there is insufficient room over the hatch for an overhead machine. The Standard Basement Set Machine has a narrow steel outboard stand to allow the traction wheel

to project into the hatch.

(at no extra cost)

*Height and width assumes 30-in sheave and 326TC motor

© 2025 VANTAGE ELEVATOR SOLUTIONS | ALL RIGHTS RESERVED | PRIVACY POLICY